We offer two levels of service for your Brass instrument:

The first level service involves: (3-months RTB warranty)

- Full clean & strip of all slides and pistons

- Chemical & ultrasonic clean of your instrument

- Pistons and slides are lapped as required

- Replace damaged spit corks as required

- Re-adjust all the mechanisms for sharp response

- Test play your instrument

The second level of service involves a full more intensive servicing: (6-months RTB warranty)

- Clean & strip faulty slides & pistons

- Chemical & ultrasonic clean of your instrument

- Pistons & slides are lapped as required

- Repair broken joints & solders

- Replace piston springs

- New felts and regulation corks

- New cork pads installed on spit valve key

- All mechanisms re-adjusted for sharp response

- Polish out unwanted labels or school engravings

- Test play your instrument

Piston rebuilds & cylindral regrinds are available for worn pistons.

The first level service involves: (3-months RTB warranty)

- Full clean & strip of all slides and pistons

- Chemical & ultrasonic clean of your instrument

- Pistons and slides are lapped as required

- Replace damaged spit corks as required

- Re-adjust all the mechanisms for sharp response

- Test play your instrument

The second level of service involves a full more intensive servicing: (6-months RTB warranty)

- Clean & strip faulty slides & pistons

- Chemical & ultrasonic clean of your instrument

- Pistons & slides are lapped as required

- Repair broken joints & solders

- Replace piston springs

- New felts and regulation corks

- New cork pads installed on spit valve key

- All mechanisms re-adjusted for sharp response

- Polish out unwanted labels or school engravings

- Test play your instrument

Piston rebuilds & cylindral regrinds are available for worn pistons.

Service: The Basics

First - we strip the instrument of it's slides, spit valves & pistons.

We examine the instrument on dis-assembly for:

- Loose posts

- Stuck slides

- Stuck pistons

- Loose mechanisms

- Worn pads

- Worn felts

- Bent slides & pistons

- Missing corks

- Major dents

- Plus many many more things!

We examine the instrument on dis-assembly for:

- Loose posts

- Stuck slides

- Stuck pistons

- Loose mechanisms

- Worn pads

- Worn felts

- Bent slides & pistons

- Missing corks

- Major dents

- Plus many many more things!

We remove the old slides by whatever means required!!

This could involve: slide hammers, penetrating oil, oxy acetalene, etc

These slides were stuck...and I mean stuck!

Look at the hard dry corrosion on the slides, a little bit of oil would have prevented this!

This could involve: slide hammers, penetrating oil, oxy acetalene, etc

These slides were stuck...and I mean stuck!

Look at the hard dry corrosion on the slides, a little bit of oil would have prevented this!

The slides are then chemically cleaned. This is to remove the internal corrosion more than the external visible corrosion.

Then into the ultrasonic cleaner!

And finally hand clean and polish

If you have been getting your instrument serviced regularly and the slides are not coming back clean like this, then find someone else!

If you have been getting your instrument serviced regularly and the slides are not coming back clean like this, then find someone else!

The same applies to pistons. How can a piston work at its best if its not spotless?

Exactly the same as the pistons - Into the chemical cleaner then the ultrasonic machine followed by a hand polish!

The instrument body now goes through the same process.

Cleaned instrument ready for re-assembly.

The slides are temporarily fitted and assessed. Any alignment issues are rectified and any binding is repaired prior to being oiled.

Slides are put home.

Pistons are going to recieve same process. They are individually checked & assessed, then straightened as required.

Plenty of oil!

The pistons are put home and functionally checked.

As part of the service, we also repair & straighten the mouthpiece.

Its good until it gets dropped again! and yes it will get dropped again.

And then it gets a final test play.

Dent repairs

Copyright © 2024 by "Musical Instrument Repairs WA (MIRWA)" · All Rights reserved · E-Mail: service@mirwa.com.au

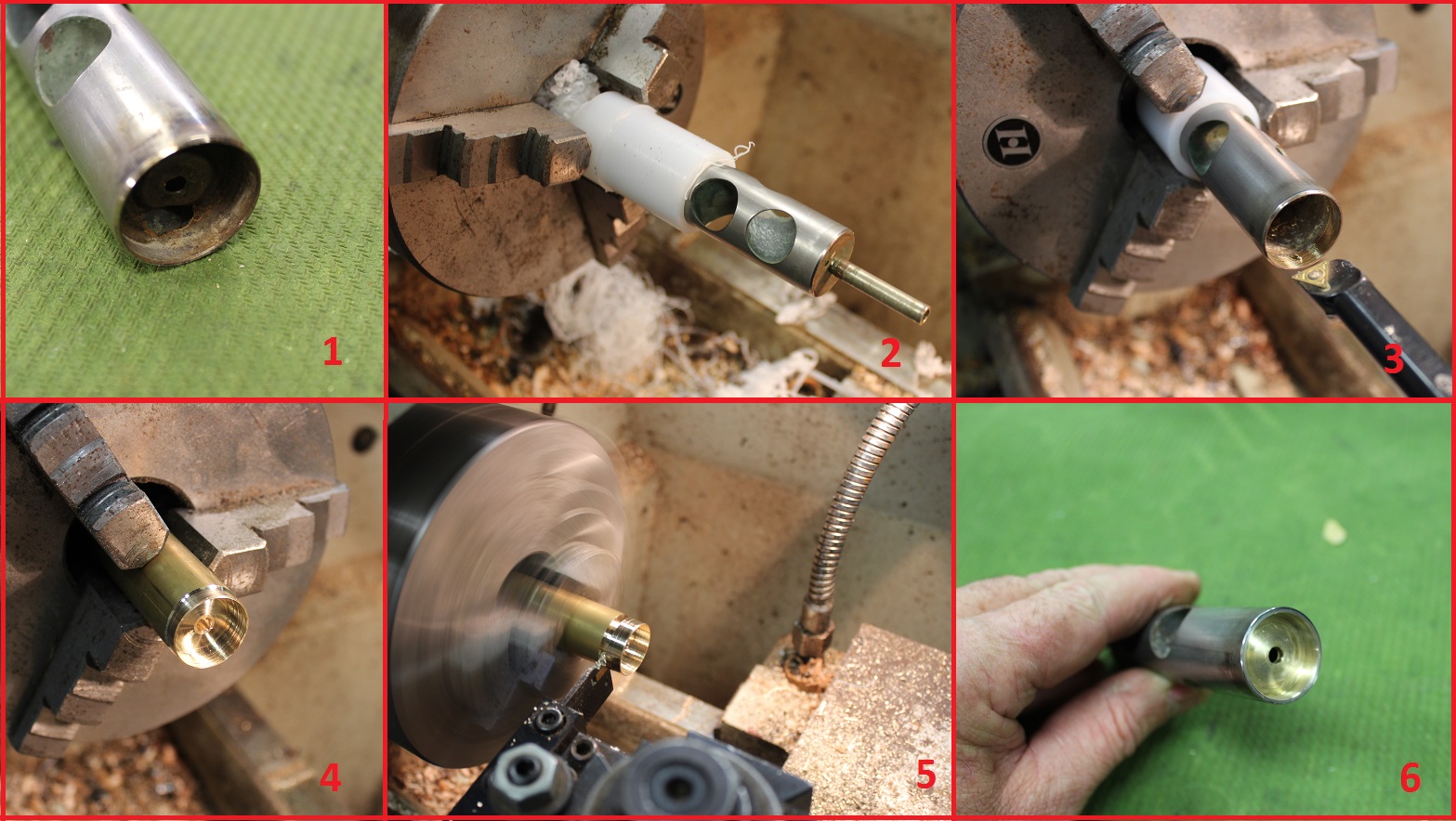

Piston Rebuilding

Double click to view

Piston Repairs

For reference,

Yes we use an ultrasonic and chemical cleaner to remove the grime and buildup inside and outside your instrument.

Consideration is given to the age of an instrument and its finish prior to doing this process.

Our ultrasonic cleaner is large enough to fit a tuba into it, attached photo shows a tuba sitting in our machine.

Yes we use an ultrasonic and chemical cleaner to remove the grime and buildup inside and outside your instrument.

Consideration is given to the age of an instrument and its finish prior to doing this process.

Our ultrasonic cleaner is large enough to fit a tuba into it, attached photo shows a tuba sitting in our machine.