Cornets / Trumpets / Euphoniums / Baritones / Alto Horns / Tubas and all forms of brass at some stage will need there pistons or valves to be rebuilt

When a Saxohpone / Clarinet / Flute and so forth get worn, we change the pads and rebuild the keywork, when Brass instruments get worn they usually get sold off cheaply on ebay.

We here at MIRWA can rebuild those valves so they perform better than when the instrument was first manufactured

Below is a brief over view of our in house process.

When a Saxohpone / Clarinet / Flute and so forth get worn, we change the pads and rebuild the keywork, when Brass instruments get worn they usually get sold off cheaply on ebay.

We here at MIRWA can rebuild those valves so they perform better than when the instrument was first manufactured

Below is a brief over view of our in house process.

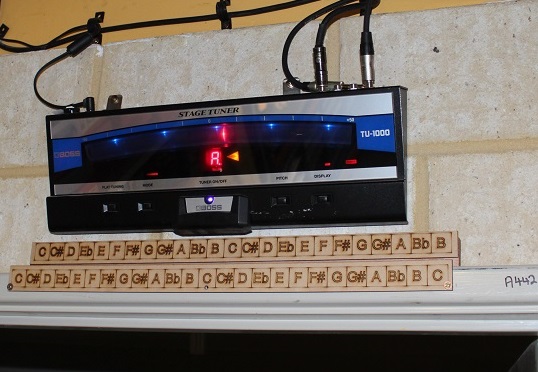

We start with a play test and check the response of the lower notes

We also cross check all notes against a tuner to see if any other tuning issues need addressing at the same time

We also cross check all notes against a tuner to see if any other tuning issues need addressing at the same time

Electroplating line for building the pistons up

A Piston plated in a build layer of copper

We now take the body and true up the chambers, using a hone

Each chamber is checked for trueness and size - we use pre machined blanks machined to a .001 difference between each size.

The pistons are then replated to .002" over the size we need in copper

The lapped pistons are re-checked in their respective chambers.

Honed Pistons and chambers are brought together and checked for the fit

The Nickel plated pistons are lapped to ensure concentricity over the length of the piston

The piston and chamber are hand lapped to each other

The Valve chamber gets a final thorough Cleaning in the ultrasonic cleaner

Copyright © 2016 by "Musical Instrument Repairs WA (MIRWA)" · All Rights reserved · E-Mail: service@mirwa.com.au

The honed pistons are then lapped, for perfect trueness accuracy to 1/10,000 of an inch

We plug the bell (sealed) and then we attach the supply hose from our test unit to the leadpipe, then carry out the pressure readings with the valves fully depressed.

Each Copper plated Piston is then honed to size for a tight fit

The pistons are then all plated in Nickel to 1 thousand of an inch thickness

The trumpet or cornet then has its chambers lapped to receive the piston.

Full assemble and test play

Pressure check of valves at completion of job

The gauge is calibrated again at 1 pound of supply pressure.

We achieve this by opening the spit valve, when we close the spit valve, the seal is so good even the supply gauge indicates some back pressure.

The gauge is calibrated again at 1 pound of supply pressure.

We achieve this by opening the spit valve, when we close the spit valve, the seal is so good even the supply gauge indicates some back pressure.

Box of Blanks all increasing in 0.001" increments

All pistons are test fitted at completion

New felts fitted on the pistons for correct alignment of the up and downstroke of the travel

The slides are all borescoped to examine the piston in the up and down position

A player usually exerts a certain amount of pressure when playing, we replicate this pressure in a closed system by applying between 1 and 3 pounds of pressure via a compressed air source .

On the test, we start with 1 pound, then 2, and finally 3 pounds of pressure.

All test readings are carried out with the valves lubricated in the normal way

On the test, we start with 1 pound, then 2, and finally 3 pounds of pressure.

All test readings are carried out with the valves lubricated in the normal way

On this cornet we are applying 1 pound of pressure.

The gauge shows that .4 pounds (ie. about half) is being lost through the valves.

.1 pound of pressure loss is within acceptable limits;

.2 pounds loss is borderline; any reading above .2 pounds indicates excess leakage with the valves needing re-building

Note: gauge 1 indicates input pressure, gauge 2 shows holding pressure

The gauge shows that .4 pounds (ie. about half) is being lost through the valves.

.1 pound of pressure loss is within acceptable limits;

.2 pounds loss is borderline; any reading above .2 pounds indicates excess leakage with the valves needing re-building

Note: gauge 1 indicates input pressure, gauge 2 shows holding pressure

With this cornet the 2nd gauge shows that the valves are leaking considerably more air when fully depressed (.5 pounds) as compared with the valves in the up position.

Note: once again, the 1st gauge indicates the input pressure while the 2nd gauge shows the holding pressure.

Note: once again, the 1st gauge indicates the input pressure while the 2nd gauge shows the holding pressure.

Once the pressure tests have been done, and assuming the results show that the valves require re-building, the trumpet is dismantled and chemically/ultrasonically cleaned.

The valve pistons are trued up to make sure they are perfectly straight and cylindrical.

The valve pistons are trued up to make sure they are perfectly straight and cylindrical.

The pistons are plastic media blasted to remove any contaminants and to provide a good base surface for the copper electroplating process.

(Our workshop has 2 blast cabinets, one for plastic media and the other for garnet grit).

(Our workshop has 2 blast cabinets, one for plastic media and the other for garnet grit).